High-Density Polyethylene pipe fittings also known as HDPE pipes are widely used due to their excellent performance. Here is a detailed overview of HDPE pipe usage in various environments, including their suitability for specific conditions such as chemical wastewater:

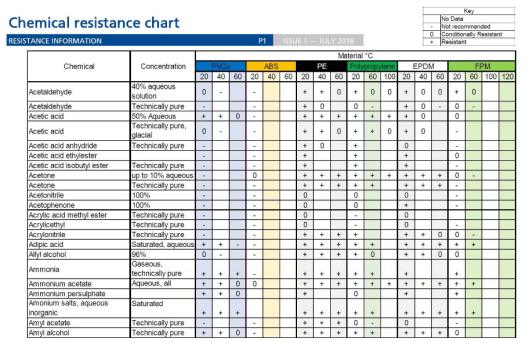

- 1. Environmental Resistance: HDPE pipe specifications are known for their outstanding resistance to corrosion, effectively resisting most acids, alkalis, and salts. This makes HDPE pipe meaning highly suitable for transporting chemicals. However, the resistance ofblack HDPE pipe to specific types of chemical wastewater or highly corrosive liquids can vary. It is essential to conduct compatibility tests based on the specific chemical composition and concentration to ensure long-term performance and safety.

- 2. Temperature Adaptability: HDPE plastic pipe operate effectively within a temperature range of -40°C to 60°C. Operating HDPE pipe outside diameter this range may lead to a decline in material properties. For instance, HDPE plastic pipes can become brittle in extremely low temperatures and may soften or deform at high temperatures. For extreme temperature conditions, additional insulation or cooling measures may be necessary to maintain the stability and functionality of the PE water pipes.

- 3. Pressure Tolerance: HDPE plastic pipes are designed to handle various pressure requirements, suitable for low to moderate pressure environments. Typically, HDPE pipe can withstand pressures up to 10 to 25 bar, depending on the HDPE pipe specifications and HDPE pipe applications needs. For high-pressure applications, it is crucial to select pipes with appropriate pressure ratings and ensure that installation and maintenance meet standards to avoid potential safety issues.

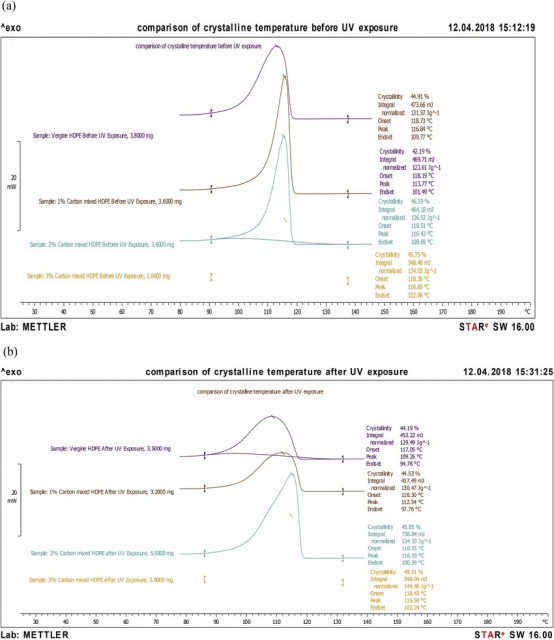

- 4. Environmental Exposure: When used outdoors, coupler HDPE pipe may be exposed to ultraviolet (UV) radiation. Prolonged exposure to sunlight can lead to material degradation and reduced strength. To counteract this, many HDPE pipe diameters are manufactured with UV stabilizers or protective coatings and buried to prevent UV damage. These measures help extend the service life of the HDPE sewer pipe.

- 5. Special Environment Applications: HDPE drainage pipe generally perform well in handling chemical wastewater and other special applications. However, the diverse and complex composition of chemical wastewater can affect the HDPE water supply pipe differently. To ensure the long-term reliability of HDPE water pipe in specific wastewater environments, detailed chemical compatibility tests should be conducted, and pipes should be selected based on the test results and required specifications.

If you have any question about the HDPE pipe for water supply, or you need our HDPE pipe and fittings catalogue pdf, please contact us freely

Your Project, Our Commitment

From design to production and delivery, we are dedicated to providing the highest quality service and products to our customers. Choosing us means not only receiving customised HDPE fittings but also having the support of a professional team to ensure smooth project execution.

Get in Touch

Feel free to customize this introduction with specific details about your company, such as your company name, years of experience, and any unique features of your products or services.