While HDPE pipe has many advantages, it also has disadvantages, such as higher cost, UV sensitivity, thermal expansion, and installation challenges.

1. Higher Initial Cost

Expense: HDPE pipes can be more expensive to purchase compared to some other materials, such as PVC or traditional metal pipes.

2. Susceptibility to UV Degradation

UV Sensitivity: Prolonged exposure to sunlight can degrade HDPE pipes, leading to brittleness and reduced lifespan. This can be mitigated with UV stabilizers but adds to the cost.

3. Thermal Expansion and Contraction

Temperature Sensitivity: HDPE pipes and fittings can expand and contract significantly with temperature changes, which may require additional design considerations to accommodate these movements.

4. Limited Temperature Range

Temperature Limitations: hdpe pipe dimensions are not suitable for high-temperature applications, as they can soften and lose strength. They also become less flexible and more prone to damage at very low temperatures.

5. Installation Challenges

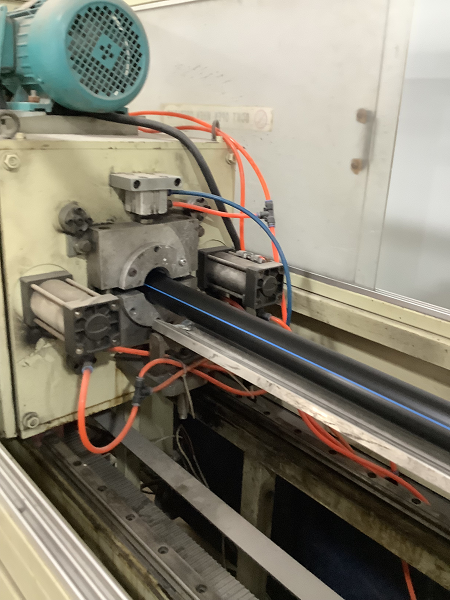

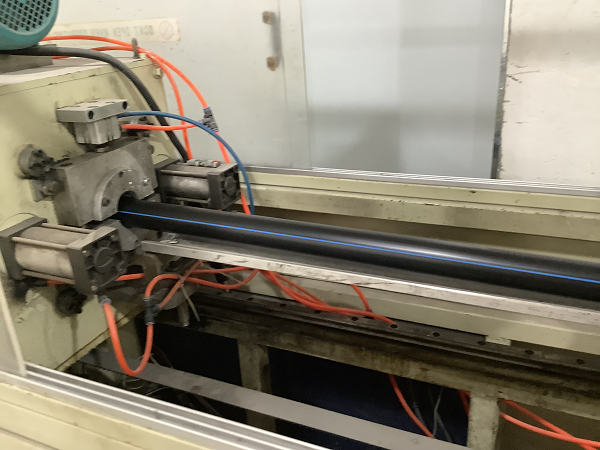

- Specialized Equipment: Joining hdpe pipe connector often requires specialized welding equipment and trained personnel, particularly for butt fusion and electrofusion processes. This can increase installation complexity and costs.

- Handling Difficulties: Due to their flexibility, large-diameter HDPE pipes can be more challenging to handle and install compared to rigid pipes.

6. Chemical Permeability

Permeability Issues: HDPE pipes can be permeable to certain chemicals and gases, which might not be suitable for all applications, particularly where containment of specific chemicals is critical.

7.Mechanical Damage

Impact Sensitivity: Although HDPE pipes are generally resistant to impact, they can be damaged by sharp objects or during rough handling. Surface scratches or gouges can reduce their overall strength and durability.

8. Potential for Water Hammer

Water Hammer Effects: Due to their flexibility, HDPE pipes can experience more significant effects from water hammer (sudden changes in pressure), which can lead to system stress and potential damage if not properly managed.

9. Joint Integrity

Joint Vulnerability: While fusion welding hdpe pipe are generally strong, improper installation or inadequate fusion can lead to joint failures. Quality control during installation is crucial to ensure long-term performance.

10. Limited Experience and Knowledge

Knowledge Gap: In some regions or industries, there may be a lack of experience or knowledge about HDPE piping systems, leading to reluctance to adopt this material or potential mistakes during installation and maintenance.

Conclusion

While HDPE pipes offer numerous benefits, including flexibility, durability, and chemical resistance, they also present challenges such as higher initial costs, UV sensitivity, thermal expansion issues, and installation complexities. Understanding these disadvantages is crucial for making informed decisions about the suitability of HDPE pipes for specific applications.

Your Project, Our Commitment

From design to production and delivery, we are dedicated to providing the highest quality service and products to our customers. Choosing us means not only receiving customised HDPE fittings but also having the support of a professional team to ensure smooth project execution.

Get in Touch

Feel free to customize this introduction with specific details about your company, such as your company name, years of experience, and any unique features of your products or services.